Mini MMA/MIG Inverter Welding Machine(Super MIG Series)

Basic Info

Model No.: MIG160SP

Product Description

Specifications Mini MMA/MIG Inverter Welding Machine(Super MIG Series)

1.Gas&No Gas available

2.Fan Cooling&Thermal Protection

3.Portable

Mini MMA/MIG Inverter welding machine(Super MIG Series) Features: • With one more MMA function. • Single-phase, portable, fan-cooling and wire Welding Machine for flux(no gas) and MIG/MAG(gas) welding. • With thermal protection, complete with MIG welding accessories. • For welding different types of materials such as steel, stainless steel. • Steel and aluminum is available on request. Supply: • OEM sevice offered: Machine Color, Color Carton, Model or Other Stuff. • With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask. • One Year Warranty. • Technical Support. Main Market: Europe, North America, South America , Southeast Asia, Middle East, Africa. Accessories: With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask.

Mini MMA/MIG Inverter welding machine(Super MIG Series) Features: • With one more MMA function. • Single-phase, portable, fan-cooling and wire Welding Machine for flux(no gas) and MIG/MAG(gas) welding. • With thermal protection, complete with MIG welding accessories. • For welding different types of materials such as steel, stainless steel. • Steel and aluminum is available on request. Supply: • OEM sevice offered: Machine Color, Color Carton, Model or Other Stuff. • With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask. • One Year Warranty. • Technical Support. Main Market: Europe, North America, South America , Southeast Asia, Middle East, Africa. Accessories: With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask.

Certificate: CE,ROHS,GS,ISO9001 Specification:

Certificate: CE,ROHS,GS,ISO9001 Specification:

MIG/MAG Welding Details: MIG/MAG welding is a semiautomatic welding process where the welding arc is formed between the material being welded and the welding wire fed through the welding torch. The filler wire is fed mechanically by the wire feeder. To protect the molten weld pool, shielding gas is also fed through the welding torch. The MIG process uses inert shielding gas (metal inert gas welding). Usually the shielding gas contains active carbon dioxide or oxygen, and therefore the most commonly used type of MIG/MAG is MAG welding. MIG/MAG is the most common welding method in today's welding industry, and also becoming more and more popular with hobby users. Benefits of this method includes high weld deposition rate and welding speed easy mechanisation and automation and wide rage of users.

Company View:

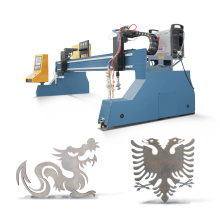

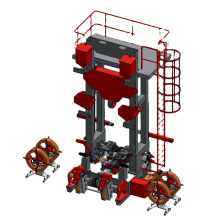

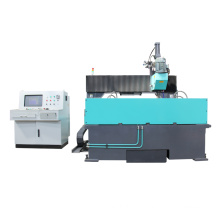

Production Lines:

Production Lines:

PCB Assembly Line & Testing:

PCB Assembly Line & Testing:

Packing:

Packing:

Contact us if you need more details on Mma/MIG welder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mma/mig、Welder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Mma/MIG welder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mma/mig、Welder. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Gas&No Gas available

2.Fan Cooling&Thermal Protection

3.Portable

Mini MMA/MIG Inverter welding machine(Super MIG Series) Features: • With one more MMA function. • Single-phase, portable, fan-cooling and wire Welding Machine for flux(no gas) and MIG/MAG(gas) welding. • With thermal protection, complete with MIG welding accessories. • For welding different types of materials such as steel, stainless steel. • Steel and aluminum is available on request. Supply: • OEM sevice offered: Machine Color, Color Carton, Model or Other Stuff. • With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask. • One Year Warranty. • Technical Support. Main Market: Europe, North America, South America , Southeast Asia, Middle East, Africa. Accessories: With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask.

Mini MMA/MIG Inverter welding machine(Super MIG Series) Features: • With one more MMA function. • Single-phase, portable, fan-cooling and wire Welding Machine for flux(no gas) and MIG/MAG(gas) welding. • With thermal protection, complete with MIG welding accessories. • For welding different types of materials such as steel, stainless steel. • Steel and aluminum is available on request. Supply: • OEM sevice offered: Machine Color, Color Carton, Model or Other Stuff. • With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask. • One Year Warranty. • Technical Support. Main Market: Europe, North America, South America , Southeast Asia, Middle East, Africa. Accessories: With standard spareparts: MIG/MAG Welding Torch, Electrode Holder, Grounding Clamp, Brush and Mask.

Certificate: CE,ROHS,GS,ISO9001 Specification:

Certificate: CE,ROHS,GS,ISO9001 Specification: | Item | MIG160SP | |

| Welding technics | MIG | MMA |

| Rated input voltage(V) | 230 | |

| Max input power(KVA) | 4.6 | 4 |

| Rated input current(A) | 20 | 17.5 |

| Efficiency | 0.8 | |

| Power factor | 0.7 | |

| Max no-load output voltage(V) | 60 | |

| Welding current(A) | 40-160 | 10-140 |

| Duty cycle(%) | 16035% | 14035% |

| 60% duty cycle, current(A) | 125 | 120 |

| Welding wire/Electrode dia(MM) | 0.8-1.0 | 1.0-4.0 |

| Insulation class | H | |

| Protection class | IP21S | |

| Measurement(MM) | 540*335*440 | |

| Weight(KG) | 22 | |

| Cod.(NO) | 113001 | |

| 20' Container Load Capacity(PCS) | 351 | |

| 40' Container Load Capacity(PCS) | 703 | |

| 40'HQ Container Load Capacity(PCS) | 854 | |

Company View:

Production Lines:

Production Lines:

PCB Assembly Line & Testing:

PCB Assembly Line & Testing:

Packing:

Packing:

Contact us if you need more details on Mma/MIG welder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mma/mig、Welder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Mma/MIG welder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mma/mig、Welder. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : MIG Welding Machine

Premium Related Products

Other Products

Hot Products

New Arrived 200A Single Phase Portable Arc Welding MachineCheap High Quality Portable Gasoline Generator for SaleCheap High Quality Small Water Pump Price for Industrial Equipment1 PHASE AC/DC WELDING MACHINEportable small plasma cutter380V spot welderAC welderNBC-315 WIRE FEEDER INSIDE professional purposeTransformer Thyristor Type 3 Phase Arc Welding Machine(ZX5 Series)Transformer Type Single Phase Arc Welding Machine(BX6-B Series)GT welding machinethermal protect welding machine(MMA115.145.165.185.205.215) SMALL WELDERnew ACDC welding machineMIG welding machineDC MMA Inverter Welding Machine(MMA-IGBT Series)